"Optimize Your Manufacturing Process with Wan Cheng's CNC Metal Form Milling Parts Service." Are you searching for a seamless manufacturing solution that blends precision and efficiency? Step into the realm of Wan Cheng's innovation with our CNC Metal Form Milling Parts Service. Specializing in on-demand metal turning and milling combined processing, we offer a transformative solution that enhances your production workflows. Efficiency lies at the heart of Wan Cheng's operations. Our CNC Metal Form Milling Parts Service integrates cutting-edge technology with expert craftsmanship to deliver unparalleled results. By consolidating metal turning and milling into a single process, we reduce production time while maximizing output, all without compromising on quality. Irrespective of your industry, Wan Cheng's CNC Metal Form Milling Parts Service is meticulously tailored to meet your unique requirements. Our team collaborates closely with you to grasp your needs and provide personalized solutions that surpass expectations." The following are product features and production advantages.

➥ Material: Utilizing Aluminum Alloy 6061-T6, renowned for its strength and resilience.

➥ Appearance: Our process fuses turning and milling, resulting in intricately formed metal parts with unmatched precision.

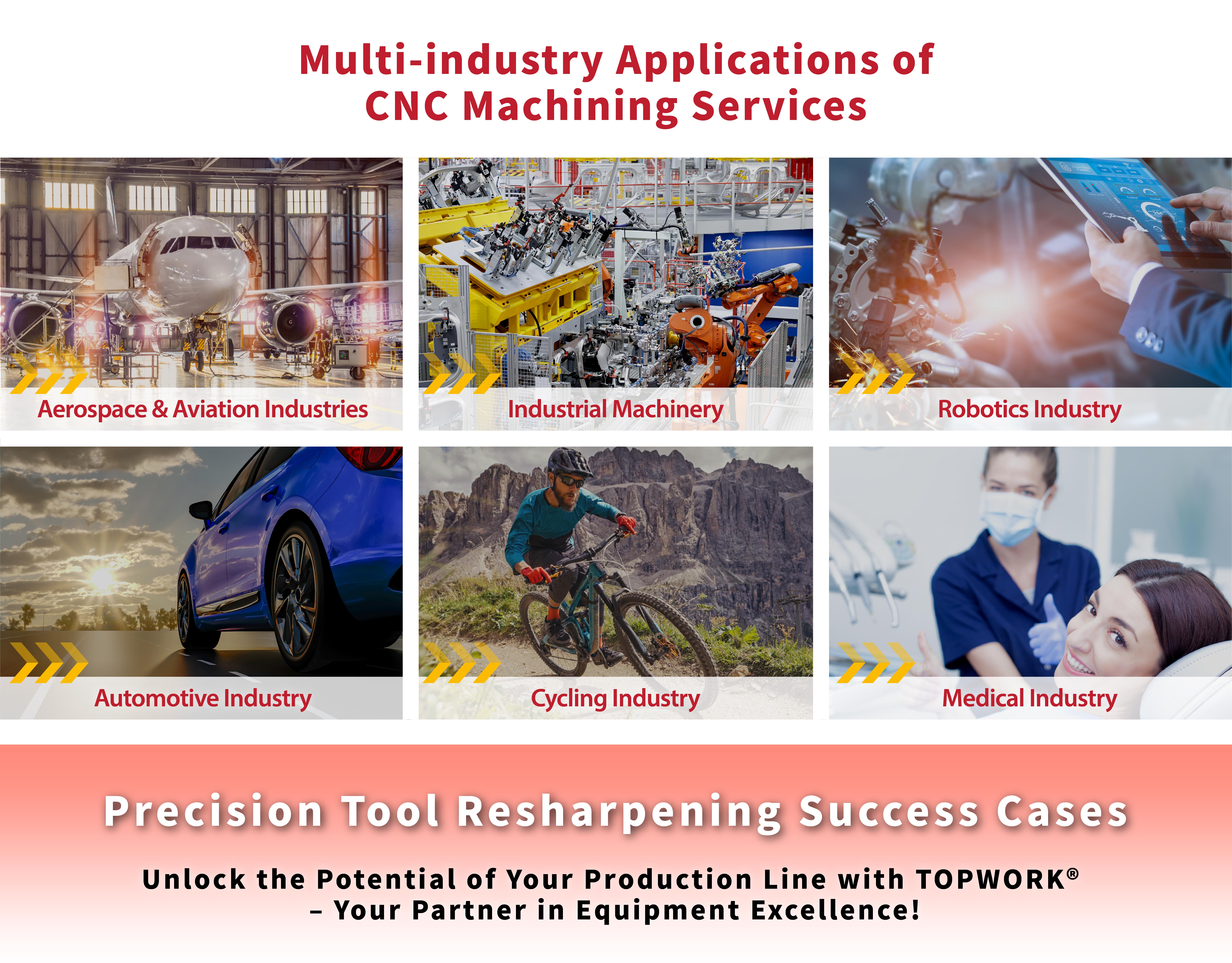

➥ Industry Applications: From aerospace to automotive and beyond, our service caters to various industries, providing solutions for OEMs, parts manufacturers, and more.

Experience the future of manufacturing efficiency with Wan Cheng's CNC Metal Form Milling Parts Service. Contact us today to discover how we can optimize your production processes and propel your business forward. Trust Wan Cheng for precision, efficiency, and innovation in metal machining.

From Aerospace to Automotive, Medical to Robotics, and beyond, Wan Cheng specializes in delivering tailored CNC milling solutions to meet the unique needs of every industry. With our advanced capabilities, we ensure precision and efficiency in every application.

✈ Aerospace & Aviation Industries: Propel your innovation forward with rapid prototyping and production for spacecraft, satellites, drones, and related components.

Medical Industry: To address the most demanding requirements of medical applications, we offer solutions for grinding zirconia, titanium, and high-end dental tools using carbide and stainless steel.

Automotive Industry: Stay ahead of the curve with customized parts for electric vehicles, molds, autonomous sensors, and more, maintaining your technological edge and development consultation.

Cycling Industry: Gain a competitive edge with custom-designed parts for electric bikes and scooters featuring unique designs, colors, and materials.

Robotics Industry: Drive efficiency and innovation in robotics with rapid prototyping and production for a wide range of applications, including industrial robot arms, smart home robots, AI robots, and robotics reducers.

Industrial Machinery: Experience unparalleled speed and efficiency in prototyping and production for industrial manufacturing, covering automation parts (FA), agricultural tools, mold making, assembly line equipment, and solutions for the chemical industry.

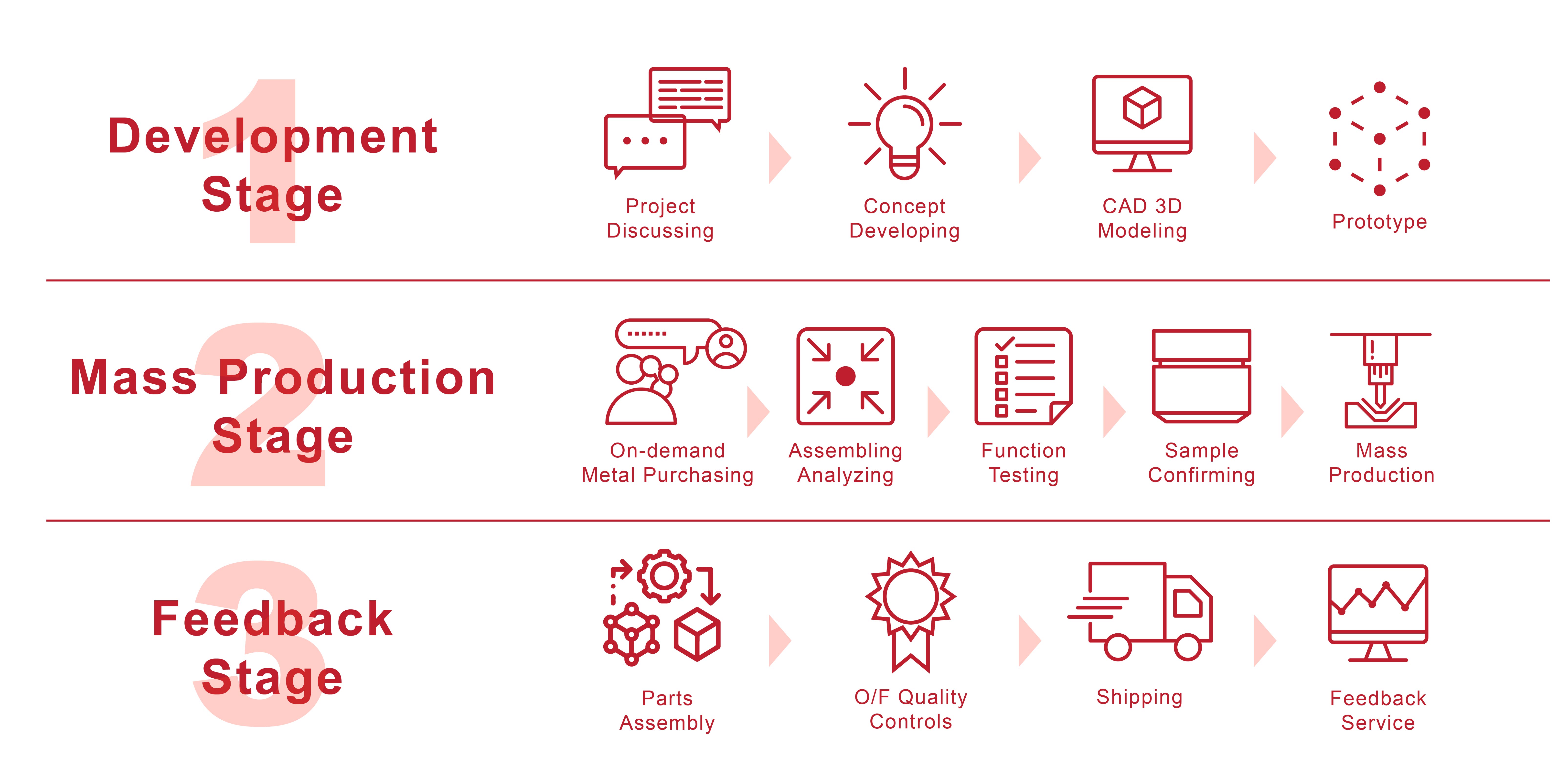

Service Process

➲ Development Stage:

During the development stage, Wan Cheng collaborates closely with the client, starting from the specifications and requirements they provide. We organize cross-functional teams to engage in comprehensive discussions, ensuring alignment between our understanding of the product and the client's expectations. Effective communication and thorough debate are vital to ensuring the perfection of our product design. Additionally, we offer rapid and reliable prototyping services for metal components, allowing clients to test and validate before formal production. These prototypes meet the demands of high-precision metal components and guarantee product reliability and performance. We can identify potential issues and make corrections promptly through early testing and validation, thus saving time and costs.

➲ Mass Production Stage:

Wan Cheng provides procurement services for various metal materials to meet diverse client needs. Whether cast iron, stainless steel, carbon steel, or aluminum alloy, we deliver high-quality machining services. Our production equipment enables various machining processes, including CNC turning, milling, drilling, etc., ensuring product accuracy and quality. With our professional expertise and advanced equipment, we achieve large-scale production, offering comprehensive one-stop solutions while ensuring product consistency and reliability.

➲ Feedback Stage:

In addition to delivering high-quality products, Wan Cheng offers comprehensive after-sales services. We prioritize assembly and logistics to ensure timely delivery and proper product functioning. Furthermore, we actively gather customer feedback to continuously improve and optimize our products and services, adapting to our clients' evolving needs. Through our comprehensive services, you cannot worry about product supply.

About Wan Cheng

Since its establishment in 2011, Wan Cheng Aviation Technology Co., Ltd. has continuously evolved and grown, emerging as a leader in the aerospace component manufacturing field. Rooted in solid professional knowledge and skills, our Wan Cheng Machine Shop in Taichung, Taiwan, commenced mechanical machining production in 2015. We proudly hold AS9100 and Hanxiang S200 certifications, underscoring our commitment to exceptional quality.

At Wan Cheng Aviation Tech, customer satisfaction is our priority. Guided by the ethos of integrity, we adhere to the principle of "Saying What We Write, Writing What We Do, and Doing What We Say." The rigorous execution of our quality assurance systems ensures that every product meets the highest standards. Equipped with state-of-the-art machinery, from lathes and milling machines to wire cutting and EDM processes, we provide comprehensive metal component solutions. Our expertise extends beyond aerospace to industries such as automotive, medical, cycling, assembly, and more.

As a forward-thinking company, innovation is ingrained in our DNA. We constantly strive for excellence, staying ahead of industry trends and offering customized solutions to meet the evolving needs of our customers. We firmly believe that continuous innovation is the key to long-term success. In the era of Industry 4.0, Wan Cheng Aviation Tech actively seeks international partnerships to shape a brighter future collectively. We eagerly anticipate the opportunity to collaborate with you and create brilliance together!

Taiwantrade.com and iDealEZ.com uses analytical cookies and other tracking technologies to offer you the best possible user experience. By using our website, you acknowledge and agree to our cookie policy.

For more information on cookies or changing your cookies settings, read Taiwantrade & iDealEZ’s Privacy Policy.